Sand is an indispensable aggregate for concrete buildings. Sand is generally divided into two types: natural sand and artificial sand. Rock particles formed by the action of natural conditions (mainly rock weathering) with a particle size of 4.75 mm or less are called natural sand. Artificial sand is also called mechanism sand, which refers to rock particles with a nominal particle size less than 4.75mm made by mechanical crushing and screening. The mechanism sand is divided into coarse sand, medium sand and fine sand according to the fineness modulus and its particle size is generally divided into 2.36-4.75mm, 1.18-2.36mm, 0.6-1.18mm, 0.3-0.6mm, 0.15-0.3mm.

The sand production line process is divided into two types: dry method sand production line and wet method sand production line. Wet method sand making line generally uses sand washing machine to clean the sieved sand to remove stone powder. The aggregate produced by wet method sand making line is relatively clean. Besides, there is no dust pollution in the air due to the wet method sand production line cleans sand and aggregates by water. The traditional manufactured sand production line adopts wet method process, and the content of stone powder is controlled through the water washing powder removing process. In the process of washing the machine-made sand, while removing dirt, impurities and stone powder below 0.075mm, the fine particles below 0.6mm are also washed away. However, it will, on the one hand,cause poor gradation of the finished products, and larger fineness modulus which reduces the strength of the concrete; on the other hand, reduced the yield, wasted resources(water pollution is more likely) and affected cleaning production. Therefore, the dry method sand production line process is more popular at present.

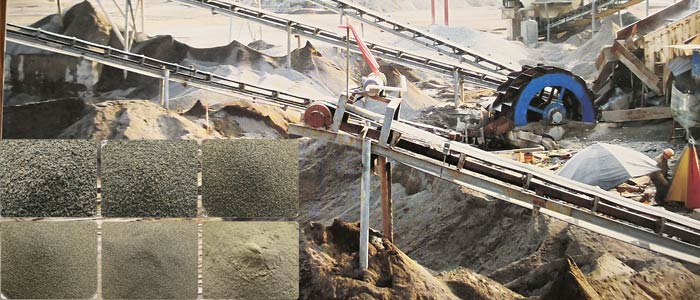

The dry method sand making process came out later than the wet process and is further introduced on the basis of the traditional wet method sand making line. The main equipment of the dry method sand production line are composed of the following equipment: hopper, vibrating feeder, belt conveyor, impact sand making machine, vibrating screen, elevator, high-efficiency separator, silo group, etc. In the dry method sand making process, the process of washing out the mud powder in the sand does not require water, so it is called a dry sand production line.

Dry method sand production is free from environmental constraints. it can save water resources and reduce water pollution, at the same time it’s equipped with powder selection and dust collection device, which is environmental friendly and can collect and utilize stone powder and adjust the gradation of mechanism sand. The dry method sand production line process represents the most advanced technology of machine-made sand at present.

CFTC provides complete set cost-effective crushing and screening equipment and sand making machine as well as high-quality sand and gravel making solutions for large-scale engineering projects such as highways, chemicals, railways, and hydropower. If you wan to learn more sand making equipment, please talk to our online service who will provide you professional advise and details for free.

*We will provide you with the most suitble producets*

*Wo Promise to reply within 24 hours.*